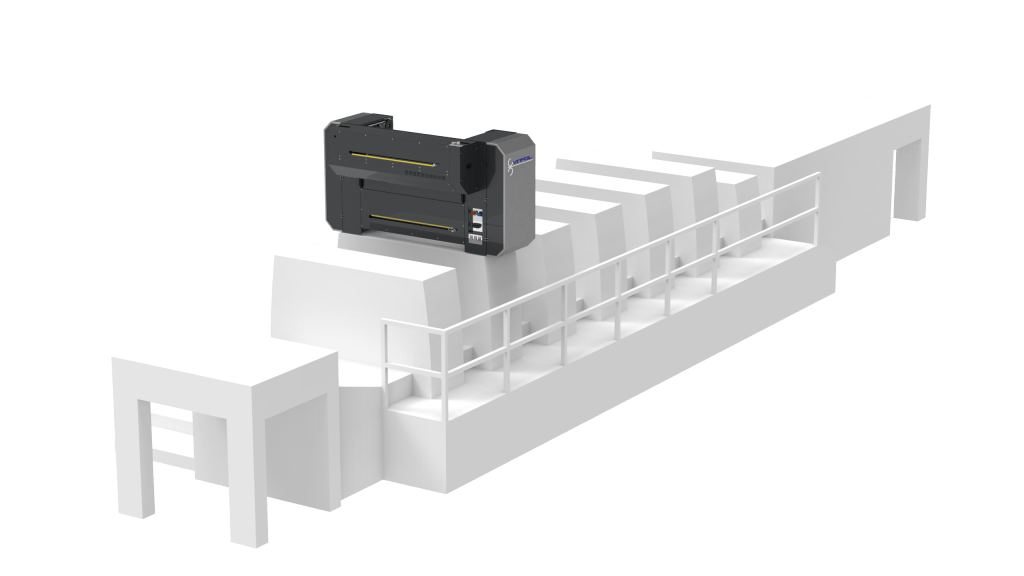

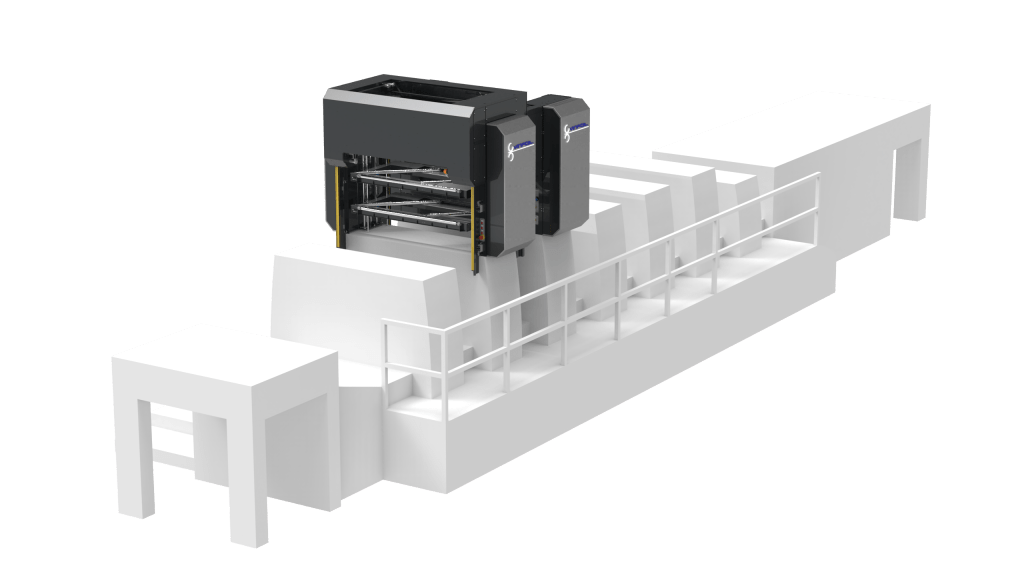

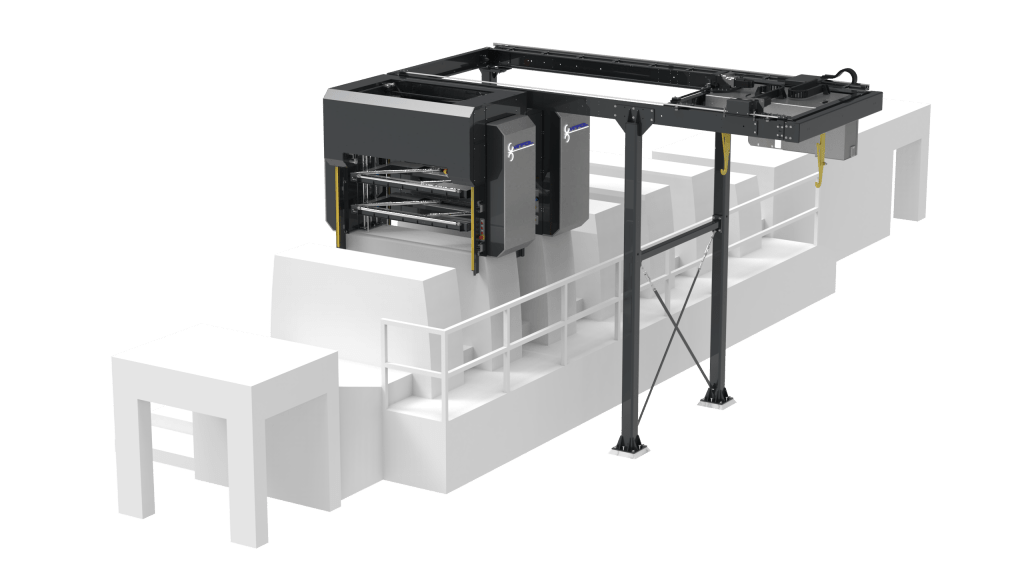

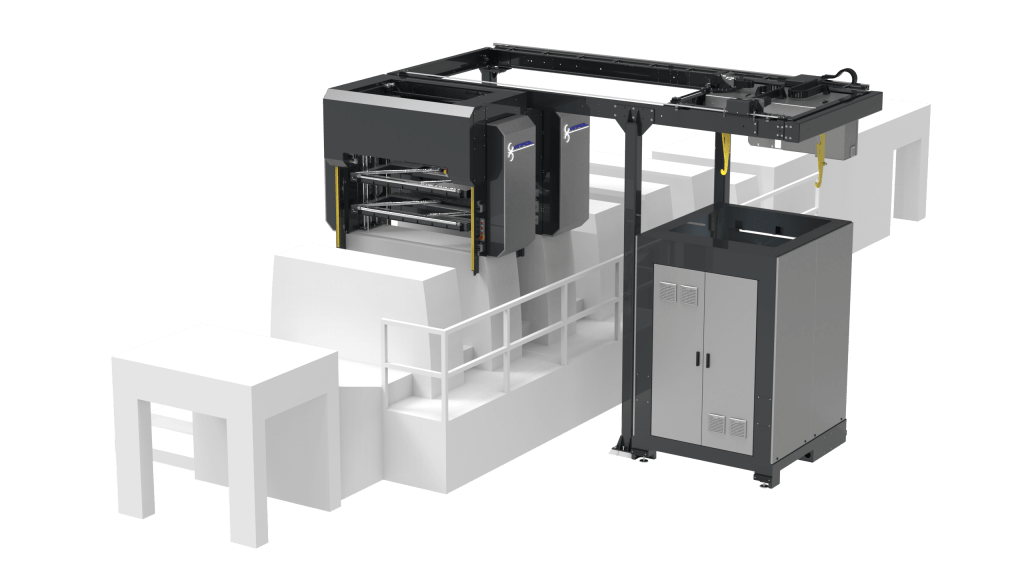

Using a standard offset plate, an image is printed onto a substrate by the use of a tacky adhesive. Foil spools from an unwind and is nipped to a substrate. The aluminium particles from the cold foil layer are released from the polyester film and transferred to the substrate by the tack of the glue.

An image with a bright surface is created on the sheet. Foil that does not adhere to the adhesive remains on the 12um film, and waste is directed to a rewind spool or to a shredder (Vinfoil Infigo systems).