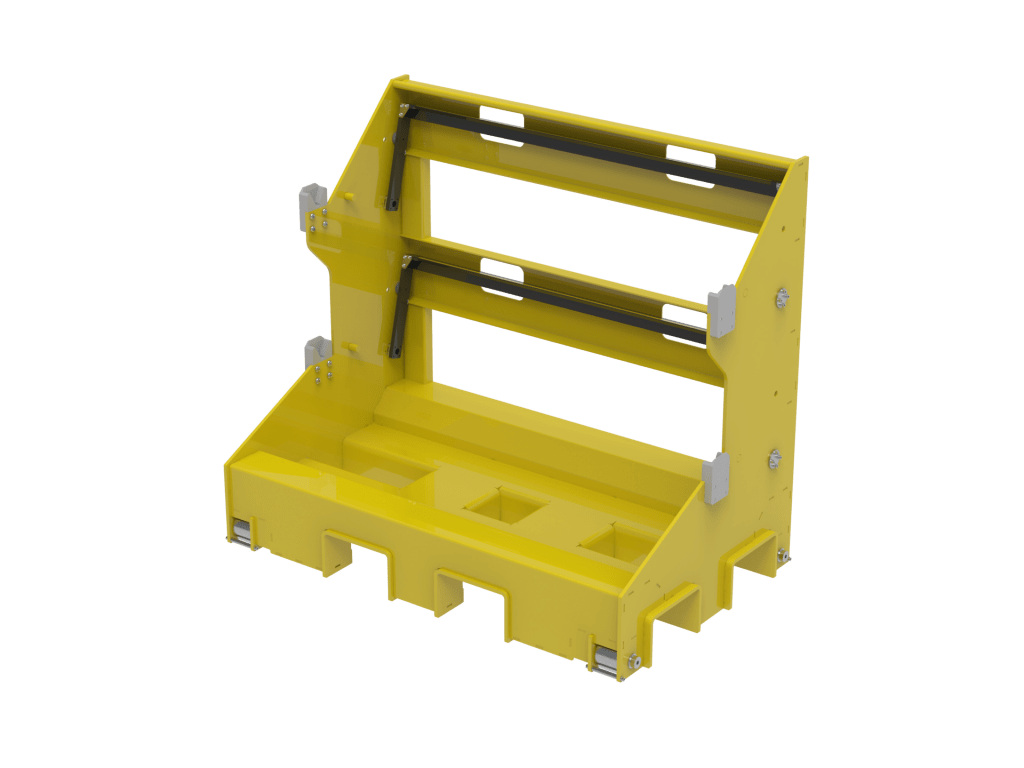

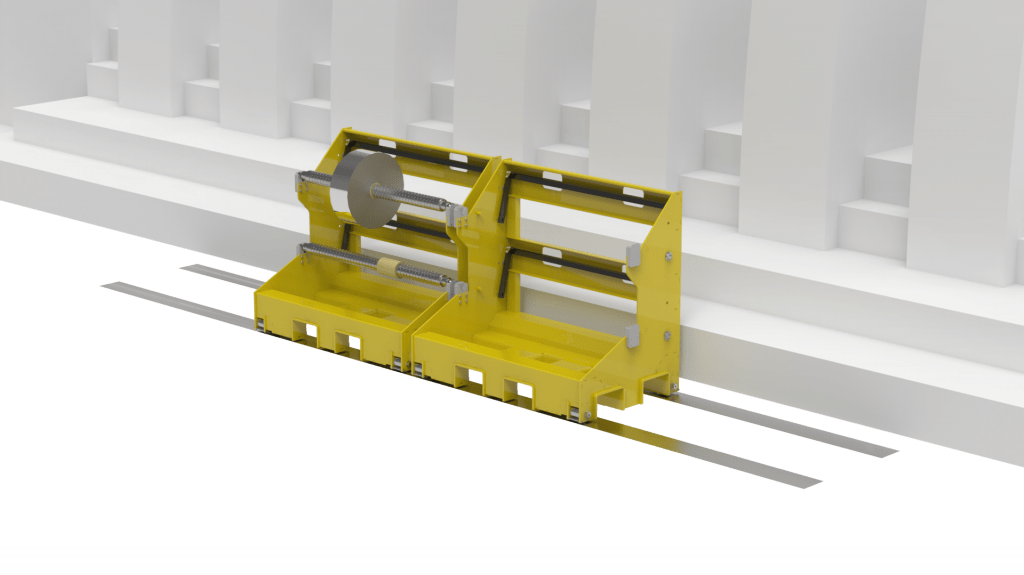

Double Shaft Preparation Frame (SPF2)

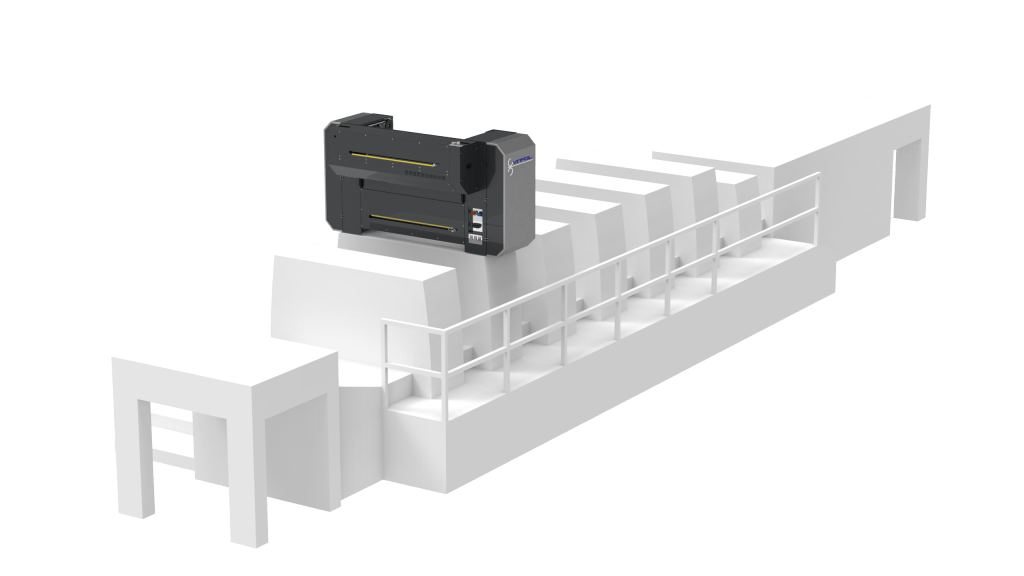

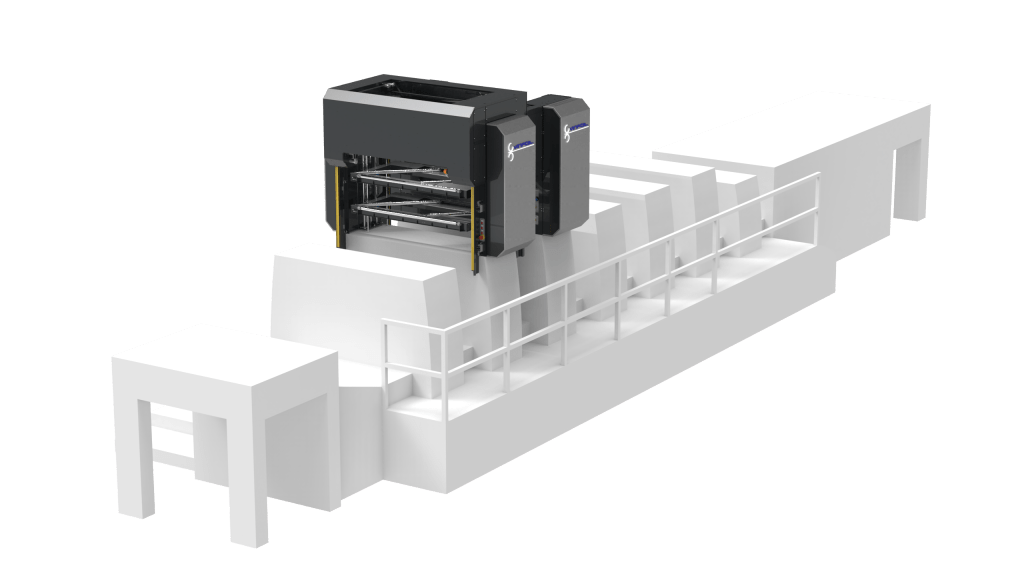

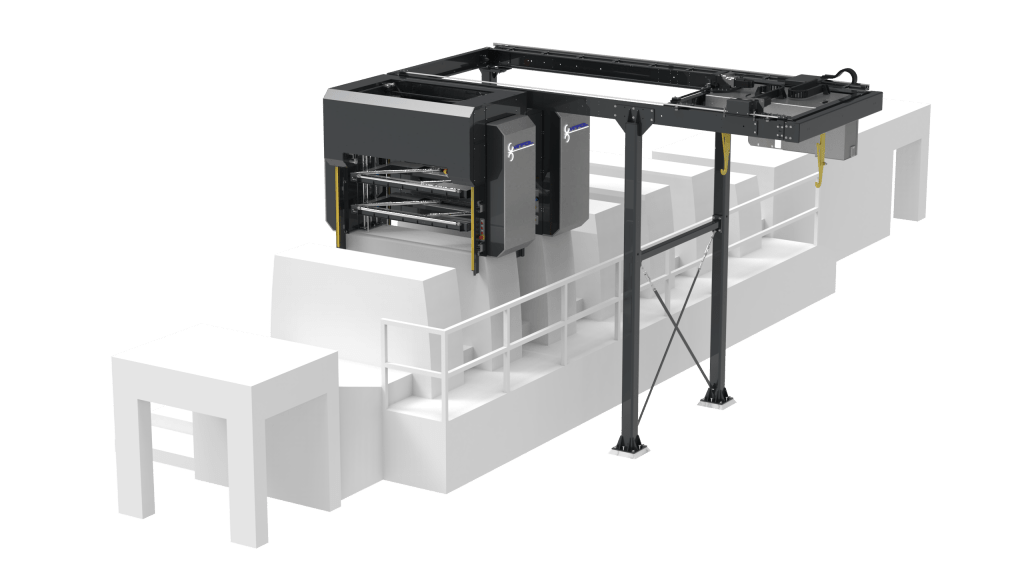

SPF2 is an easy tool for preparing fresh reels and empty cores before or during production. The MFSC exist of 2 SPF frames, one extra frame and: Integrated rulers for optimum reel placement. Easily transportable by forklift or pallet truck. Can be positioned on the operator side or the drive side of the printing press 2 (two) additional 3” bi-directional locking shafts