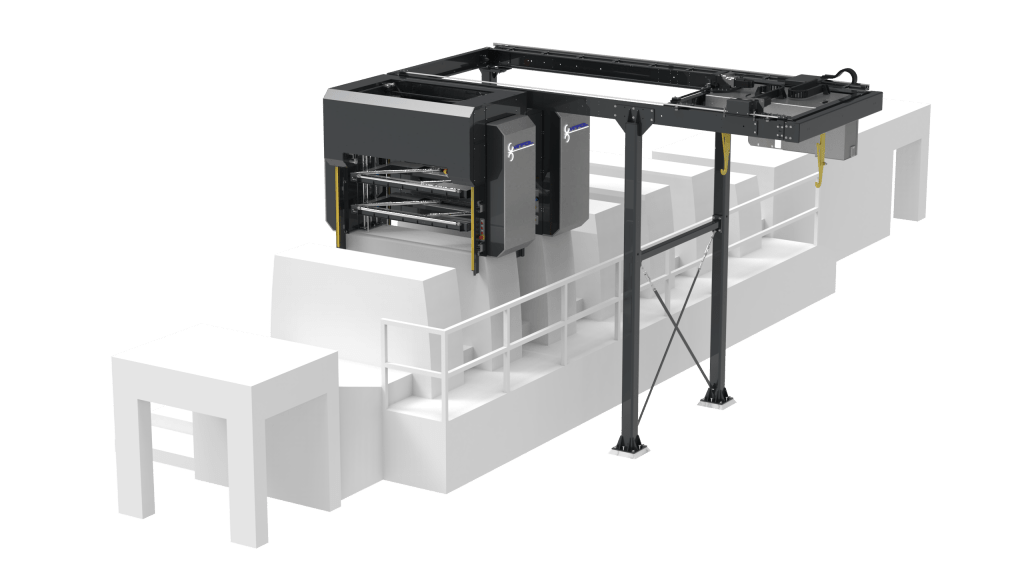

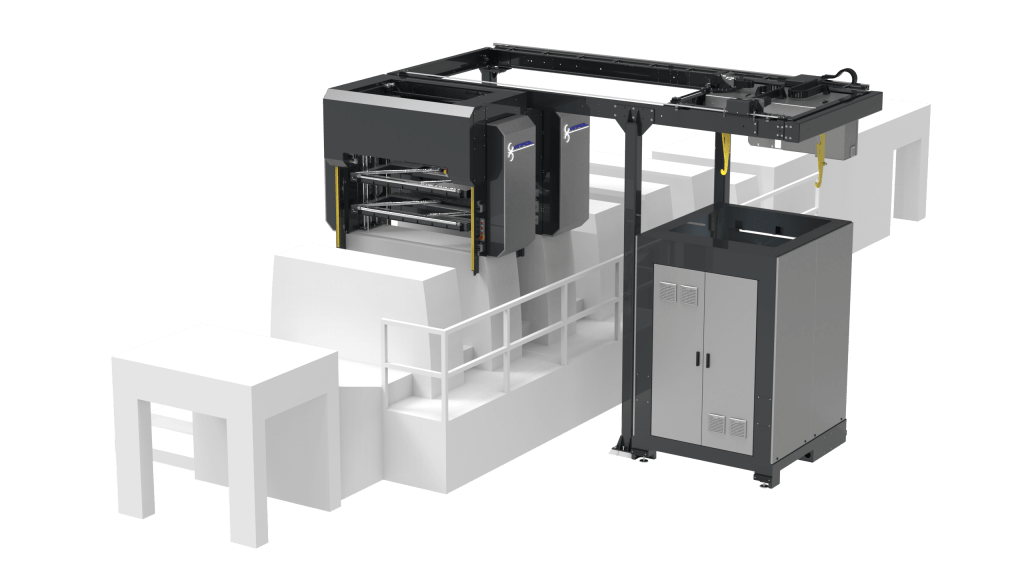

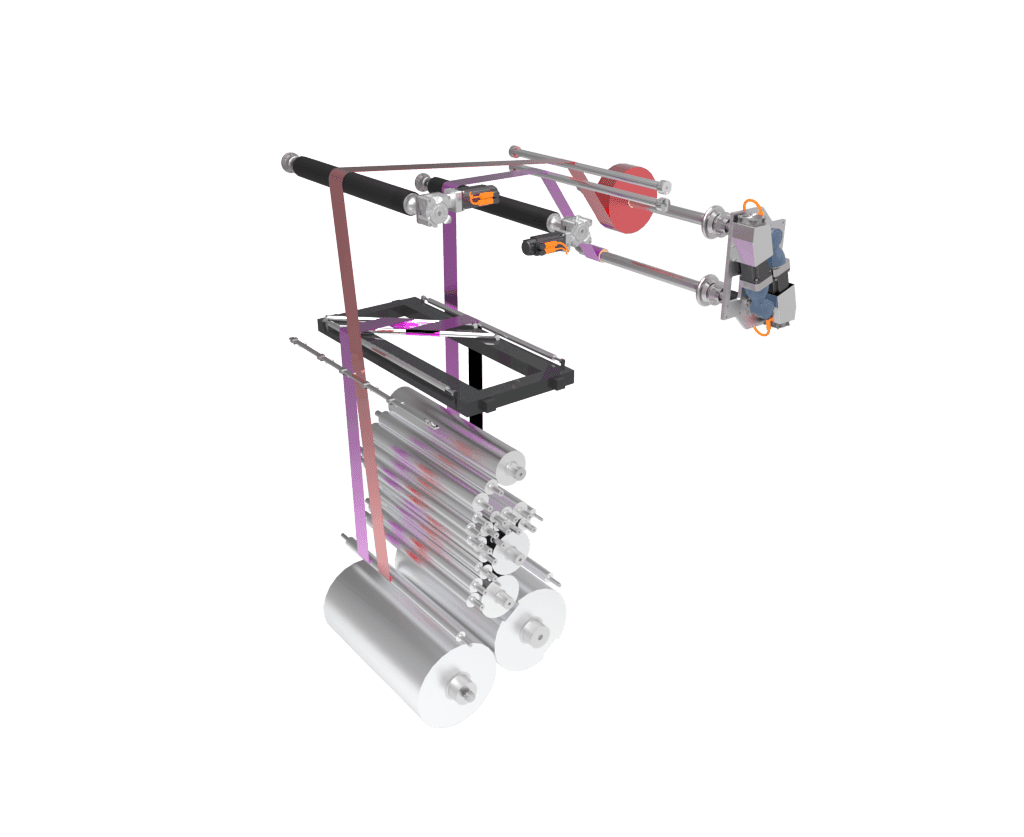

MFU

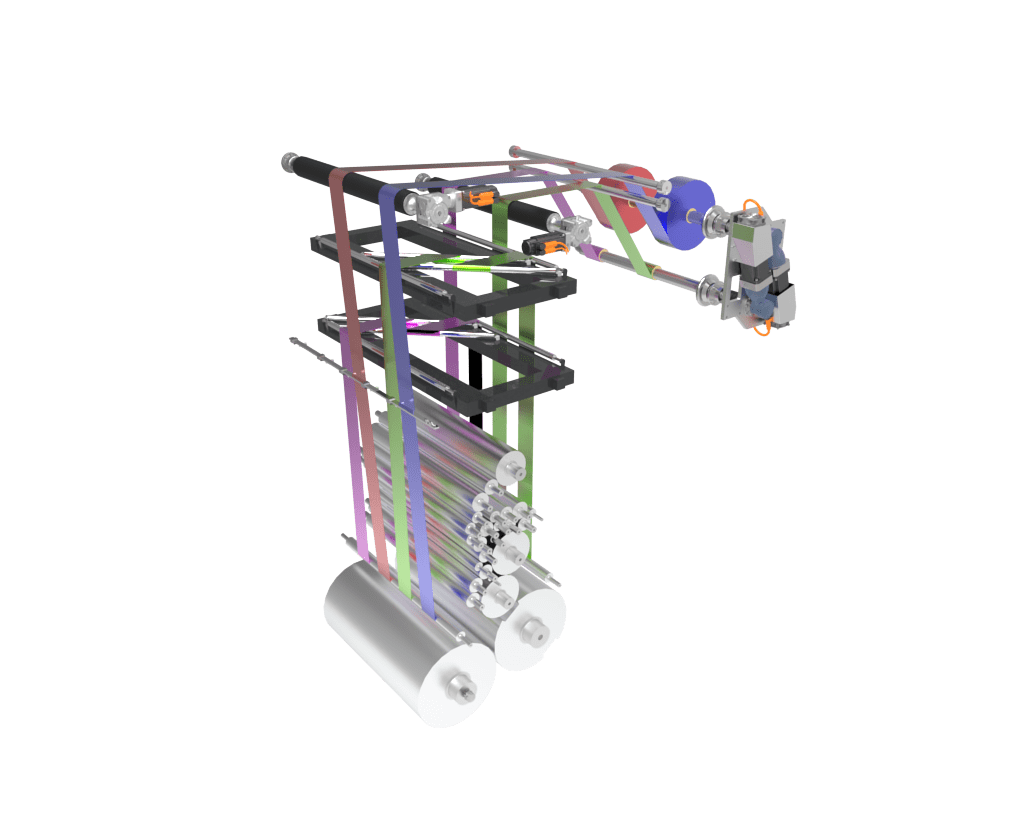

One MFU® deck with horizontally movable turn bars provide lateral adjustment of the foil web position. With this technology, one foil web can be used up to 2 at the same time, reducing the cold foil consumption up to 40% compared to full web productions or metalized board.